PVC Paneling Industry

What is PVC Paneling? What is Plastic Paneling?

PVC paneling panels are the material that will save you money and time ....

Plastic paneling The main thing in the panel is its unpretentiousness. PVC paneling can be used everywhere (except for rooms where the temperature exceeds 87 ° C: under these conditions, irreversible processes will begin to occur in the PVC paneling, it will begin to deform). The plastic panel will behave perfectly in a humid environment, and nothing will happen to the PVC panel even if it is in water for a long time.

As for the cold, PVC Paneling has proven itself, but with a little caveat. In cold weather, the PVC Panel becomes brittle and any mechanical impact on the Plastic Panel may cause damage and destruction. We now turn your attention to the decorated PVC Paneling (i.e. colored Plastic Paneling, also painted).

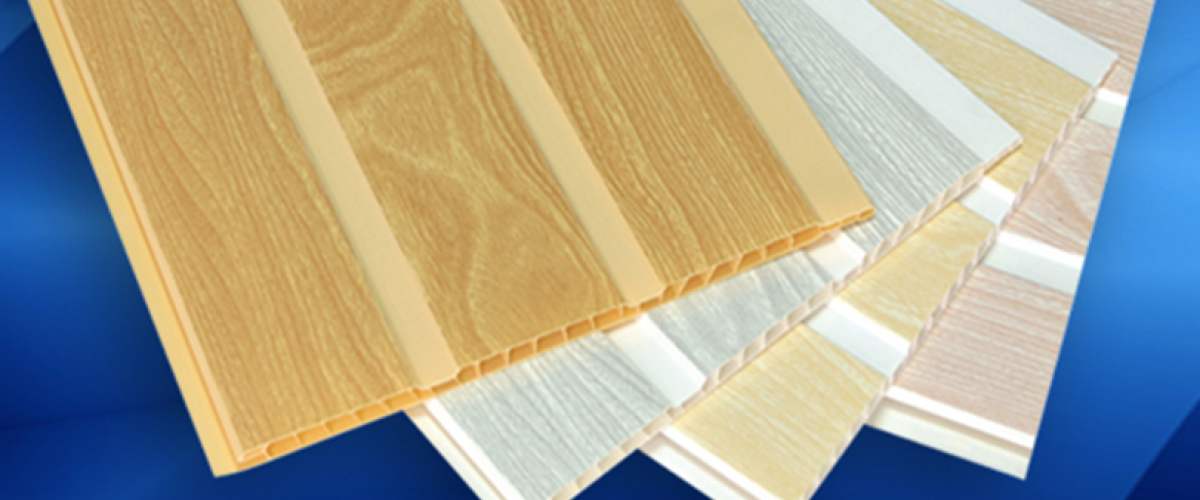

Colored PVC paneling is divided into several types, depending on the type of coating:

- offset printing: A PVC paneling is rolled with a special roller on a white base, then varnished and dried using a UV lamp. In this case, PVC paneling is obtained with a pattern and varnished. The plastic wainscot panel achieves a glossy surface.

- thermal transfer printing: again, a solvent composition is applied to the white base of the PVC Paneling Panel, which dissolves the top layer of the PVC Paneling Panel. Then, a film with a certain pattern is wrapped on the PVC Panel. In this case, the PVC panel acquires a semi-gloss structure.

-lamination : in this case, the color of the base of the PVC Paneling Panel does not matter, since the entire base is covered with a thick PVC film (a similar piece of furniture is used for the manufacture of MDF facades in the manufacture of furniture). After applying the PVC paneling film, PVC paneling gains additional strength and enhanced aesthetic properties.

What is better to choose from the listed types of PVC panels?

Let's start in order ...

Offset printing: This PVC paneling is used more often for ceilings than for walls. When using PVC paneling in bathrooms, the problem of maintaining a PVC paneling arises. Condensation accumulating on the plastic paneling leads to the formation of a whitish coating on the PVC panel, which is very difficult to remove from the surface of the PVC panel due to the gloss (polishing) of the PVC panel. Almost all cleaning (wiping) of the PVC panel leads to the formation of small scratches, which are then clogged with dirt, and the PVC panel is unsightly.

Thermal transfer printing: A PVC panel made in this way is more practical in decorating any building with a Plastic panel. The film layer covering the plastic wainscot panel is more resistant to mechanical stress. Therefore, if you use the Plastic Panel in the bathroom, you will have no problem getting the plate out of the water. Still an undeniable plus, this type of PVC wainscoting panel has a large number of color solutions. The standard length of the panels is 2.7m and 3.0m.

Laminated PVC panel: This version of PVC wainscoting panels has high surface resistance to mechanical stress. But in such panels there are still more minuses than pluses. The most obvious minus is an extremely small color range (mostly wood textures), followed by a high price.

From the above information, the result shows itself. The most suitable Plastic paneling for interior decoration is a PVC paneling made by thermal transfer printing.